AMT Vertical Tower Mill

Introduction & Features

ATM INDUSTRY AMT series Vertical Tower Mill is mainly used in the crushing and grinding of metal ores, the crushing and deep processing of non-metallic ores, the comprehensive utilization of low-grade minerals, the extraction of useful elements from tailings and other mining industries, powder metallurgy, mechanical alloying, metallurgical raw material treatment, utilization of metallurgical waste residue, cemented carbide production and other industries.

AMT is used to grind and refine particles by stirring. Under the stirring of the agitator, the medium ball and mineral aggregate in the mixing tank perform multi-dimensional circular movement and self rotation movement. The gravity generated by the medium ball and mineral aggregate and the centrifugal force generated by the rotation are comprehensively used. The impact, friction and shearing effects are generated between the medium balls, between the mineral aggregate and between the medium ball and mineral aggregate. The mineral aggregate is deformed, fractured and finally crushed under the action of momentum and impulse to achieve the ideal particle size. Under the same power, compared with the traditional ball mill, the energy saving is 30%~50%. The smaller the product size, the more obvious the energy saving effect. The maximum feeding particle size can reach 6mm, and the minimum discharging particle size can reach 0.02mm. The spiral vertical mill is a kind of ultra-fine grinding equipment, which grinds ores or other materials with a certain particle size into finer particles.

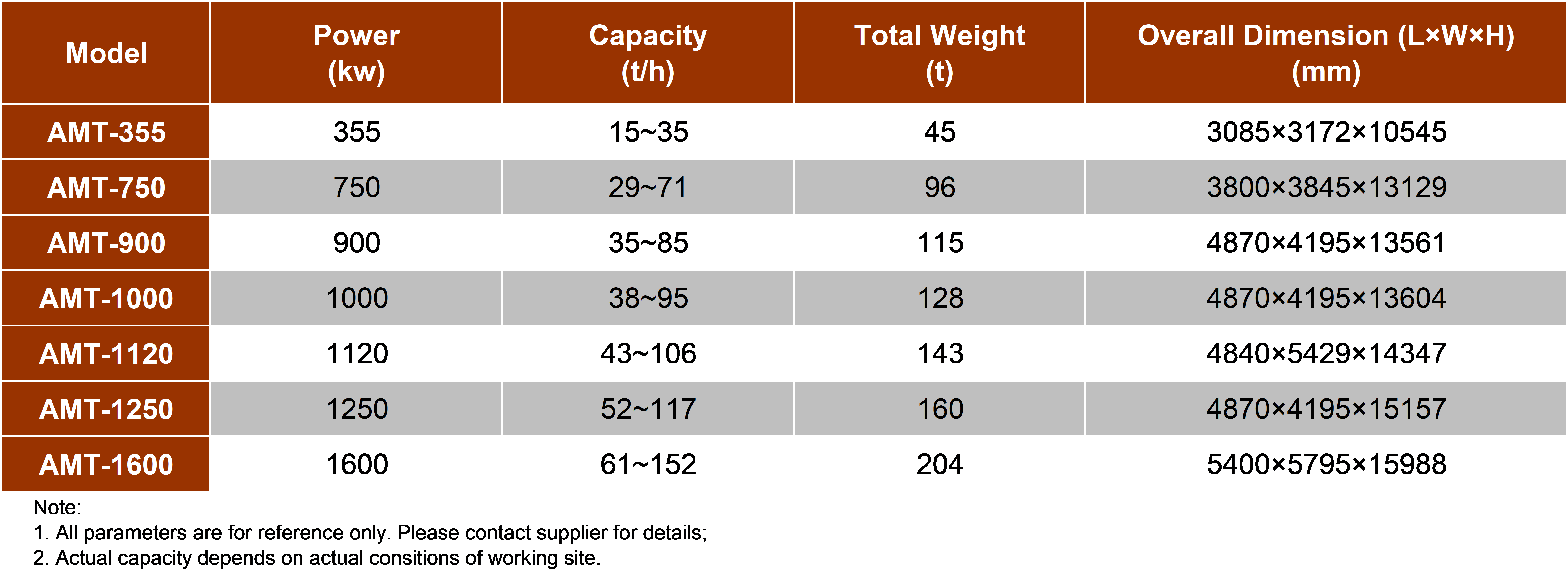

Technical Specification

@copyright Ausino Technological Manufacturing Industry Co., ltd.