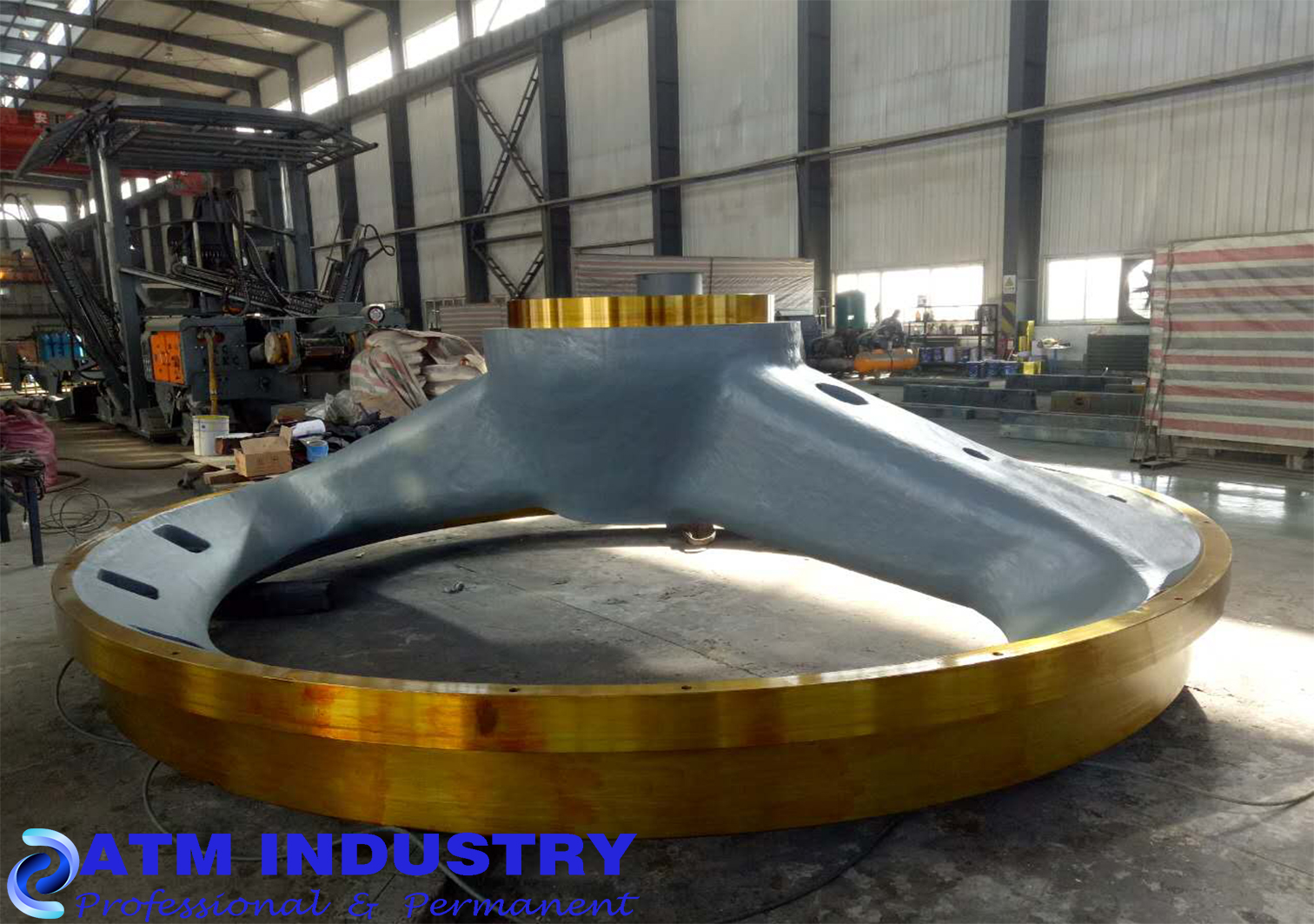

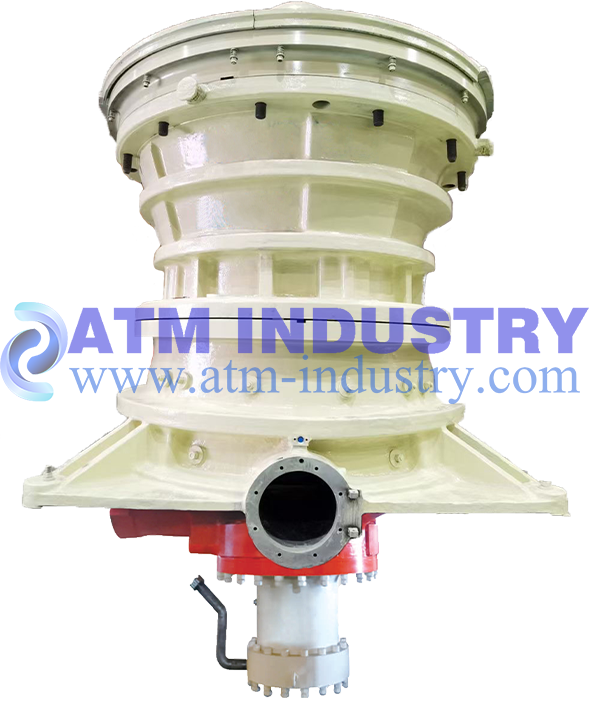

AG Gyratory Crusher

Introduction & Features

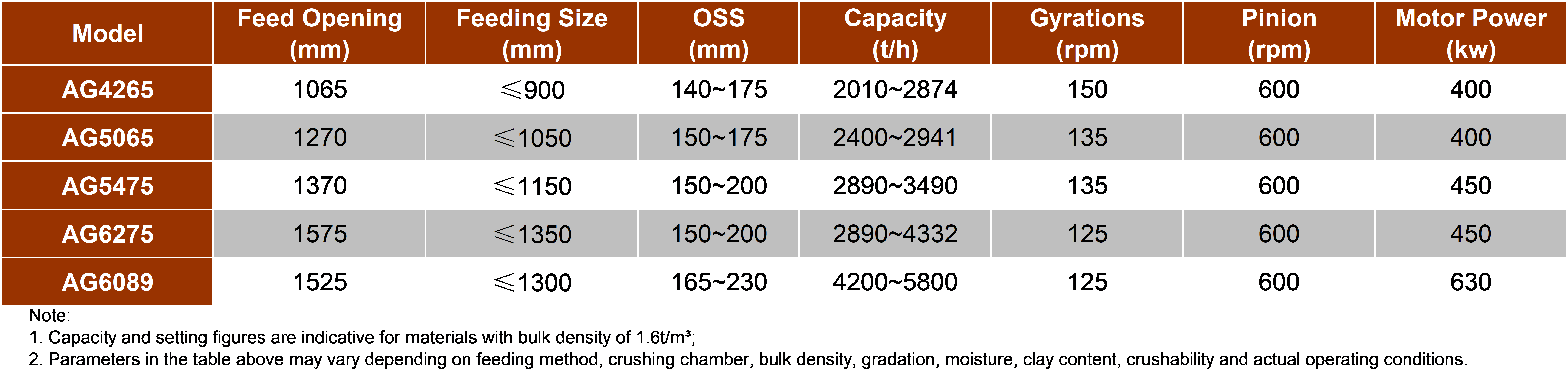

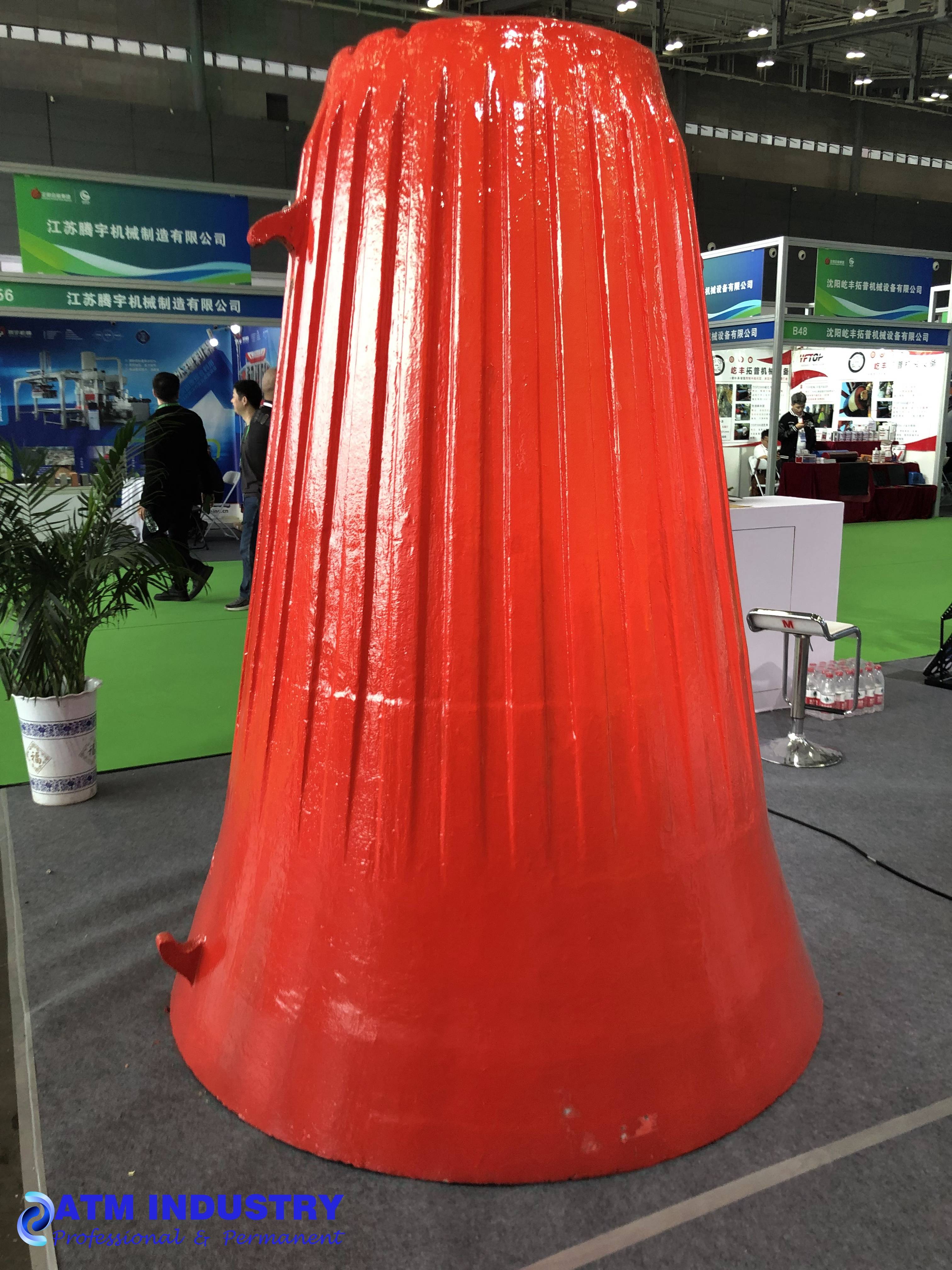

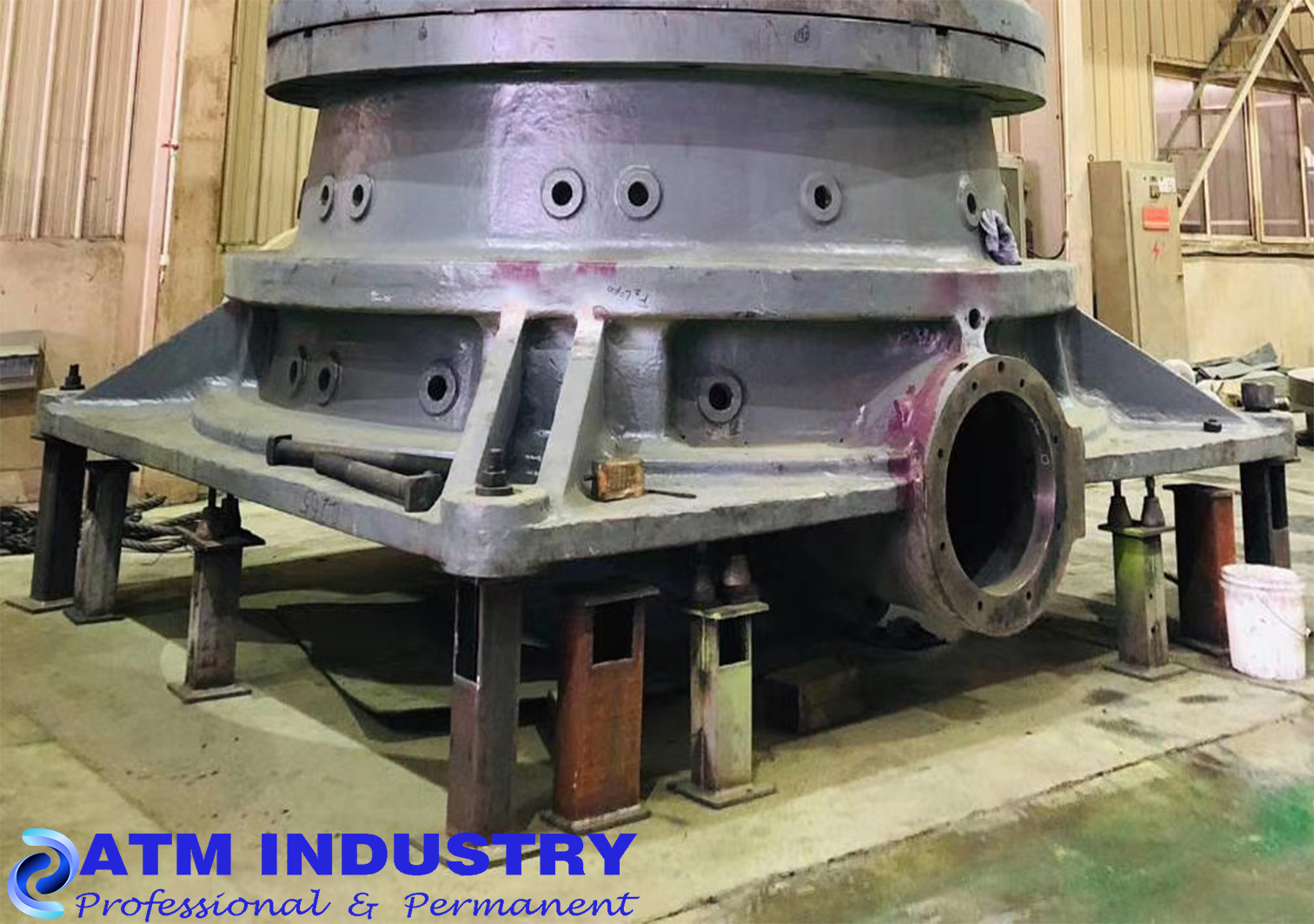

ATM INDUSTRY has taken original design, technology and fabricating process of international famous crusher brand, all components perfectly interchangeable. AG series Gyratory Crushers, incorporates all of the heavy-duty design features of heavy cast-steel frame sections, forged main shaft and countershaft, robust gearing, generous lubrication, long-life bronze components. We also focus on coupling these historical characteristics with updated maintenance friendly features.

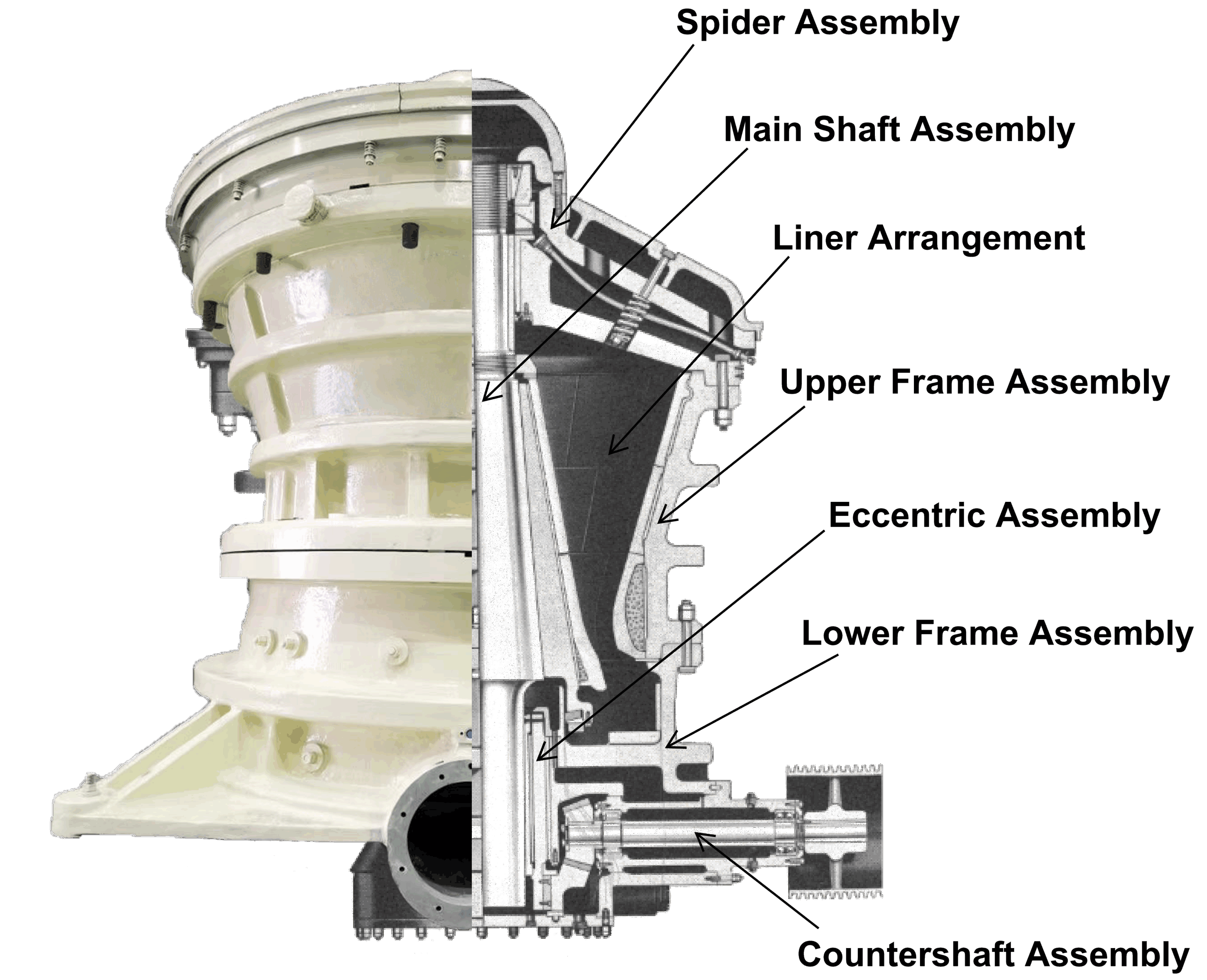

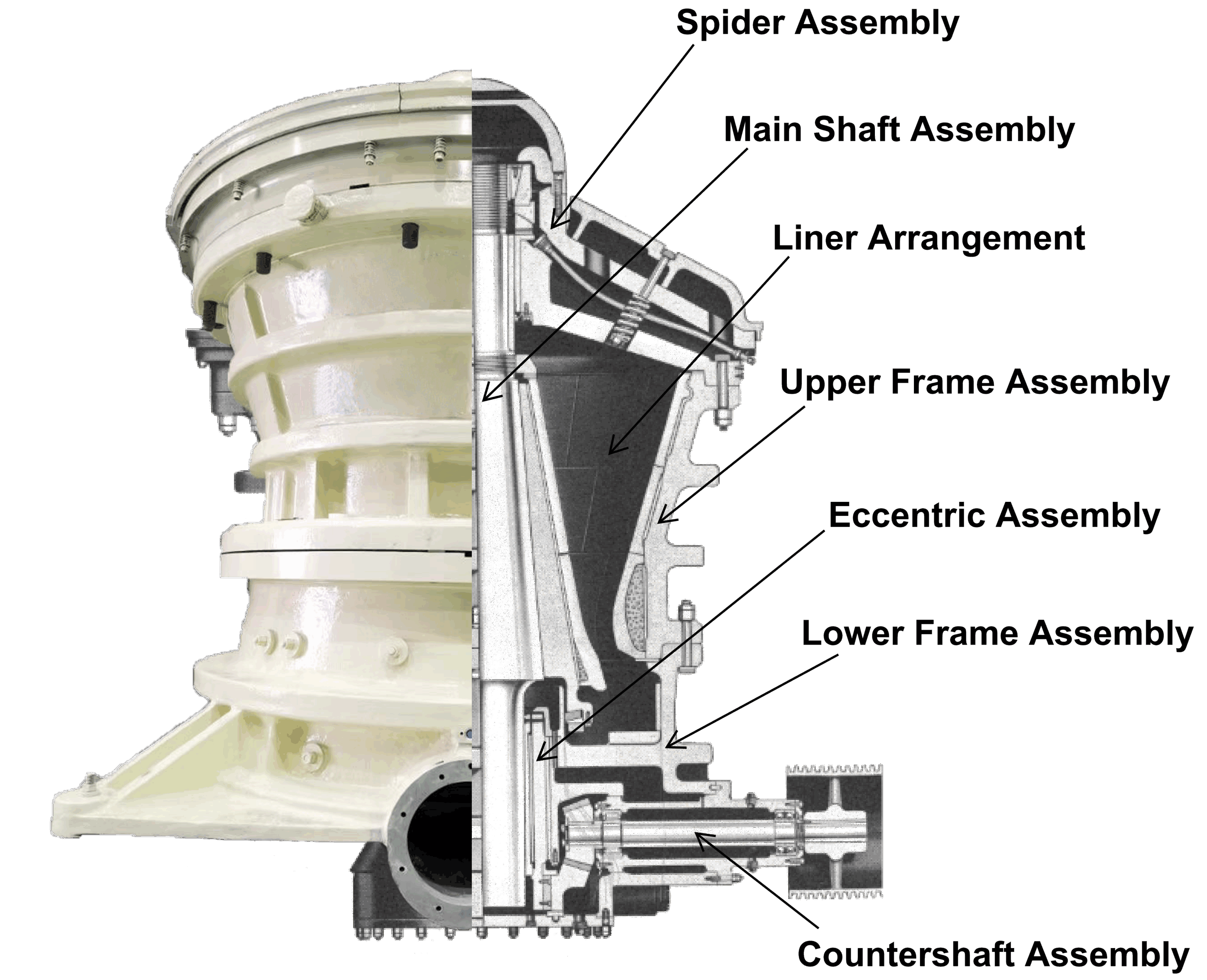

Phosphorous bronze spider bushing provides longer life as compared to “cast iron” bushings. Tapered spider bushing can be removed and installed without removing the main shaft.

The main shaft assembly is designed with a threaded sleeve to remove stress rising from the forged shaft and self-tightening head nut to assure security. Self-lubricating contact dust seal prevents contaminants from entering oil.

The risk of burned bushings is minimal during demanding crushing operations because of large capacity reservoirs and high oil flow rates to eccentric and shaft bushings.

Large face width spiral bevel gear set achieves strength and durability ratings by greater contact area rather than extreme surface hardness. Less risk of tooth failure due to shock loading.

Rotatable countershaft assembly allows for fine tuning of gear backlash. Preloaded self-adjusting tapered roller bearings automatically adjust to temperature fluctuations and wear, eliminating need for manual endplay adjustment.

Multiple oil seal design provides positive barrier to oil loss and dust contamination.

Main Structure

@copyright Ausino Technological Manufacturing Industry Co., ltd.