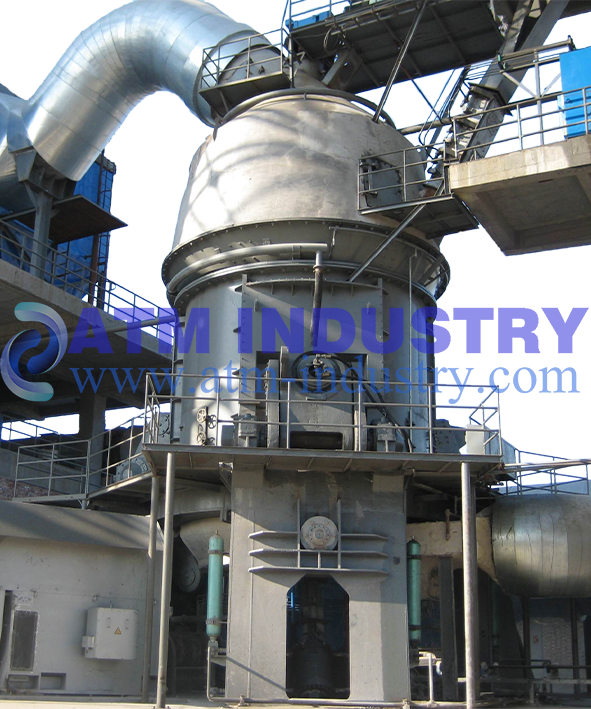

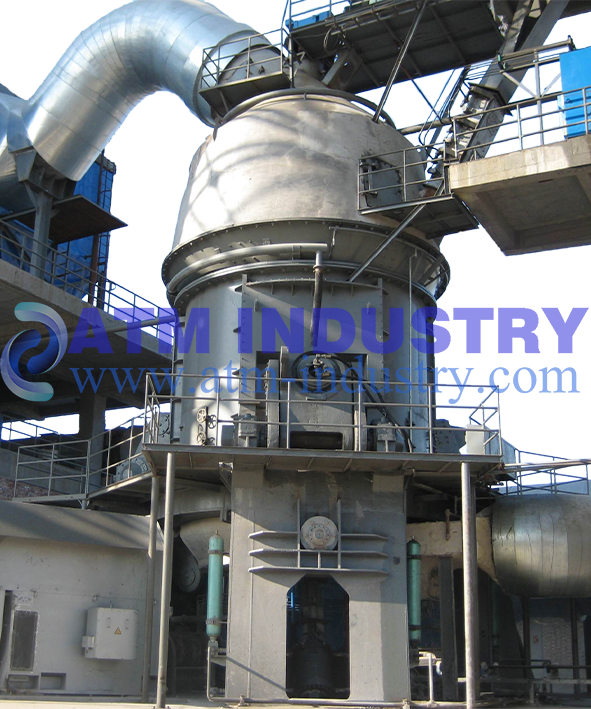

AMV Vertical Roller Mill

Introduction & Features

ATM INDUSTRY AMV series vertical roller mill is the professional micro-powder grinding equipment, imported and improved advanced technology, design and fabricating process from Pfeiffer. So far, we have owned types of vertical roller mill: AMV-S Slag Mill, AMV-C Pulverized Coal Mill, and AMV-R Cement (Raw Meal) Mill. AMV perfectly solved ‘stable material layer to prevent vibration’, ‘tramp iron release in mill’, ‘wearing resistance of grinding roller & bowl liner’, ‘high-efficiency separator’.

Composite Wearing Liners – Grinding Roller and Bowl adopt composite material liners with wear layer by 60-70mm, and cemented carbide overlapped welding technology.

Dynamic & Static Separator – AMV adopts Dynamic Separator and Static Separator. Rotary speed could slow down below 90rpm. Classification resistance and rotor abrasion can be decreased greatly. Also, independent Gas Pressure Sealing Device decreases air leakage effectively.

Separately Pressurized Grinding Roller – Grinding Roller adopts separately pressurized system with grinding pressure up to 1.2Mpa. Pressurized roller can compact the loose material quickly, and be furnished with damping limit device, forming the stable material layer. Roller liners adopt cemented carbide overlapped welding technology.

Versatile Grinding Bowl – Sealing device prevents powder leakage and reduces noise effectively. Retaining ring could extend material’s retention on grinding bowl. Water-spray device will stabilize the material layer. Radial adjustable nozzle ring will help to provide the suitable air-speed. Tramp iron releasing device will run while milling. Bowl liners adopt cemented carbide overlapped welding technology.

Backpressure Damping Hydraulic Variable Loading System – Grind Rollers will fulfill dynamic lift-and-swing, increasing the operation efficiency of mill.

The material feeds through Three Gas-lock Valves, and lands in the center of Grinding Bowl along feeding chute. The material will be well ground by compression and friction between Grinding Bowl and Grinding Roller. Meanwhile, the centrifugal force by rotary roller will force material to move to and climb over the edge of bowl, then the material will be blown up into the Separator by the hot gas from Nozzle Ring. The Separator will select out qualified micro-powder while the unqualified coarse material will return to grinding bowl for regrinding.

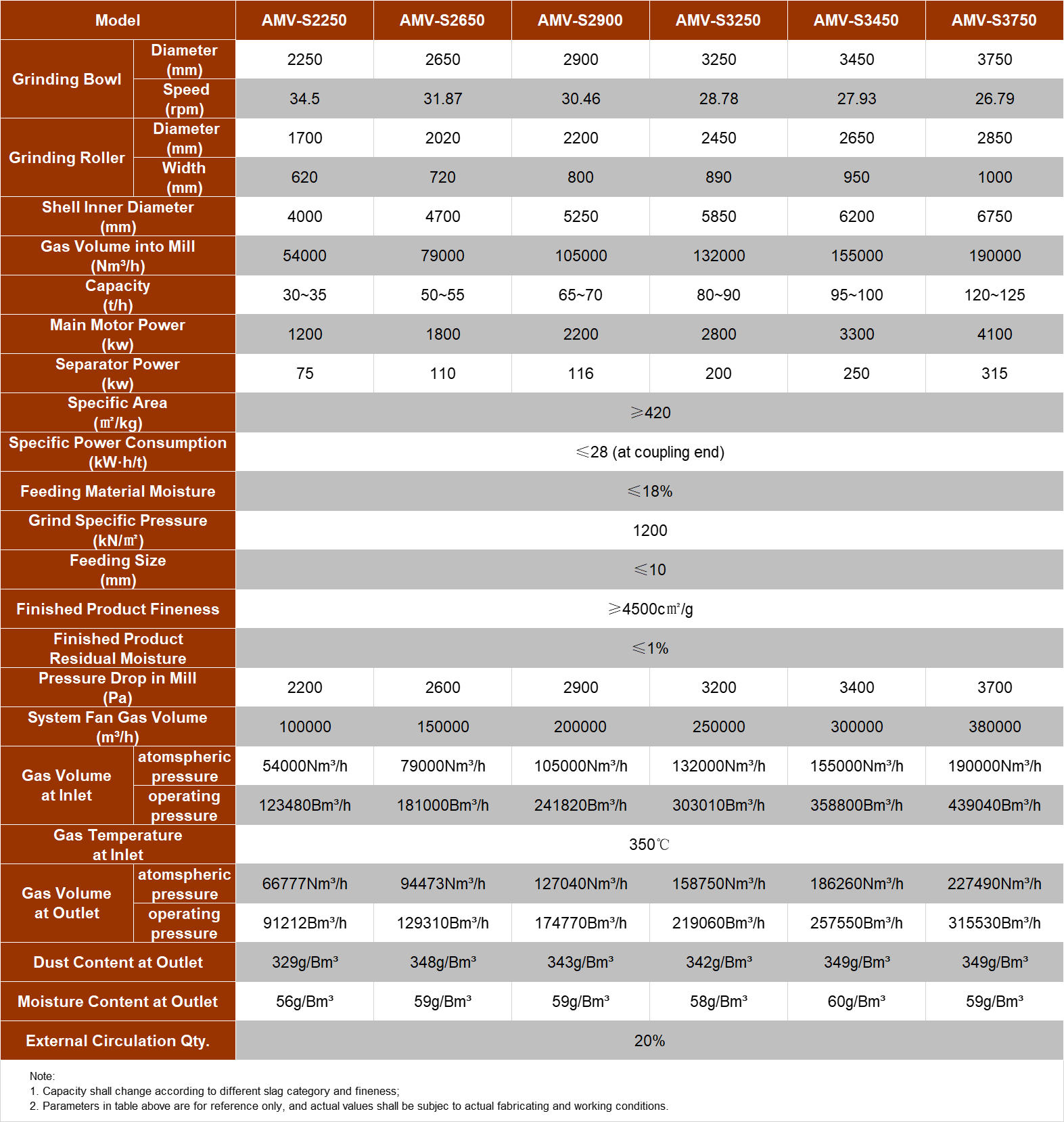

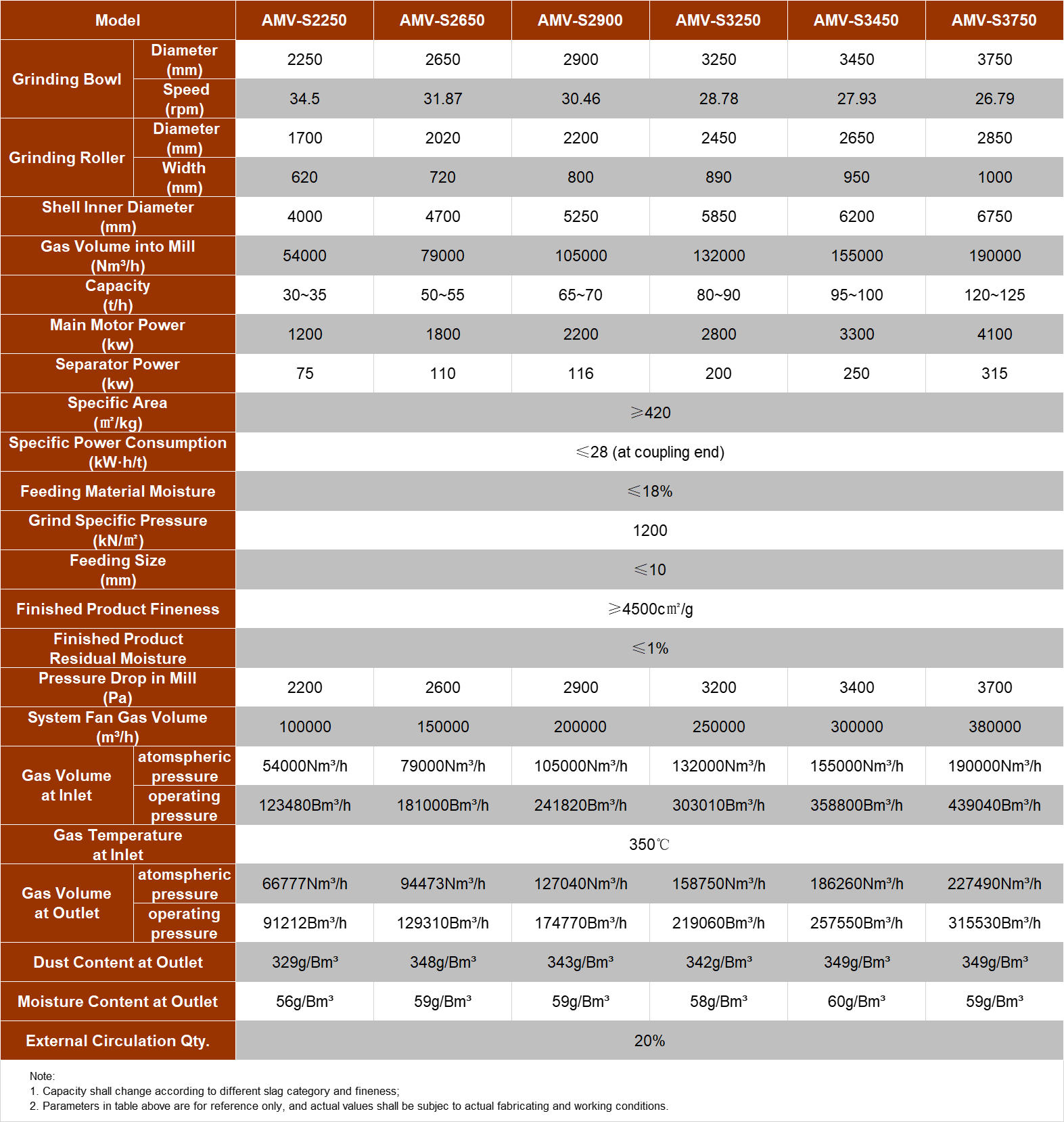

AMV-S Slag Vertical Roller Mill

AMV-S Slag Vertical Roller Mill can provide slag micro-powder with specific area above 400㎡/kg, and the finished product is one key green building material as cement substitute. 1 ton slag powder will reduce consumption of 1.5 ton limestone, 100kg coal and 50kWh electricity, as well as 0.8 ton CO2 emission, enhancing cement early strength and concrete performance.

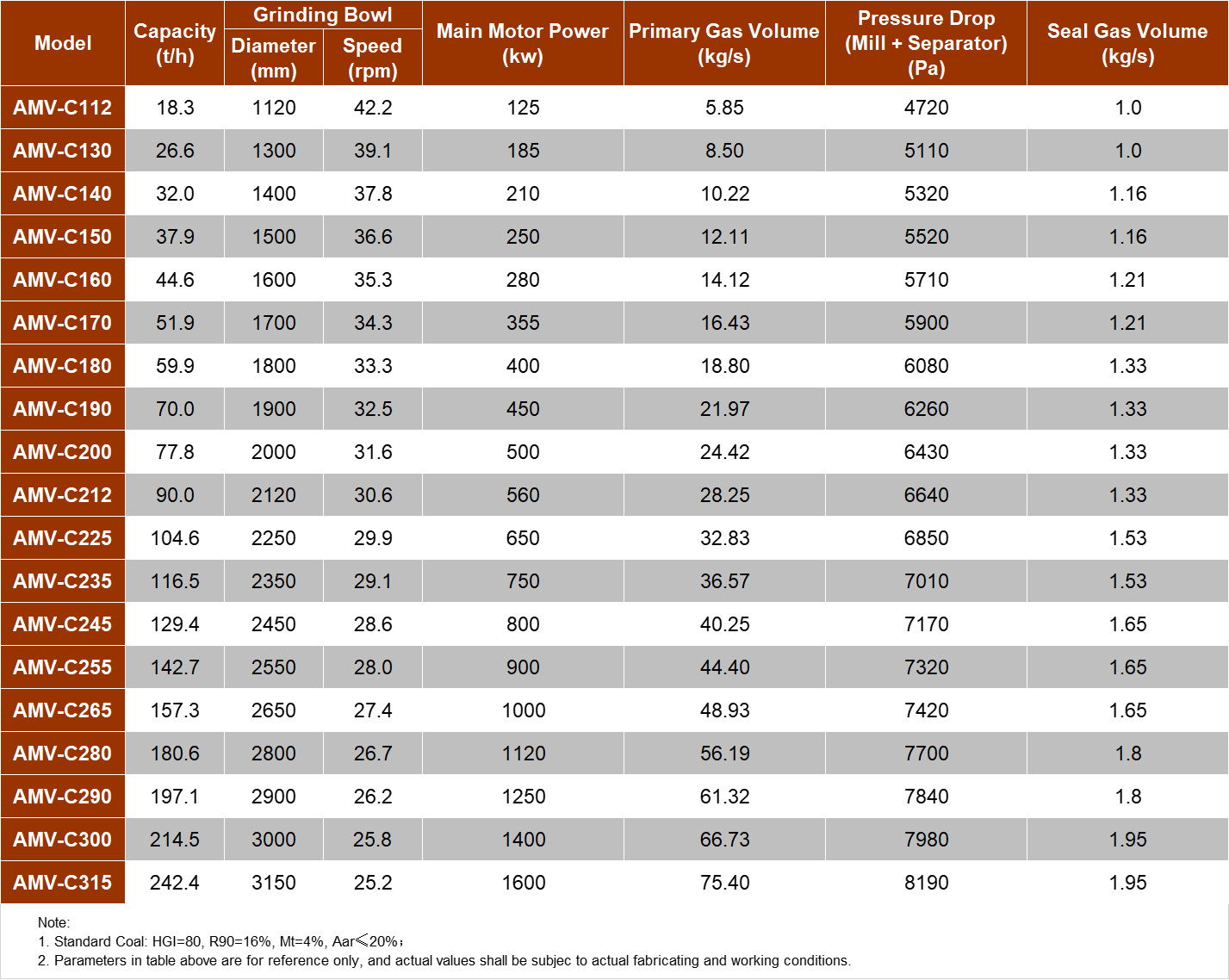

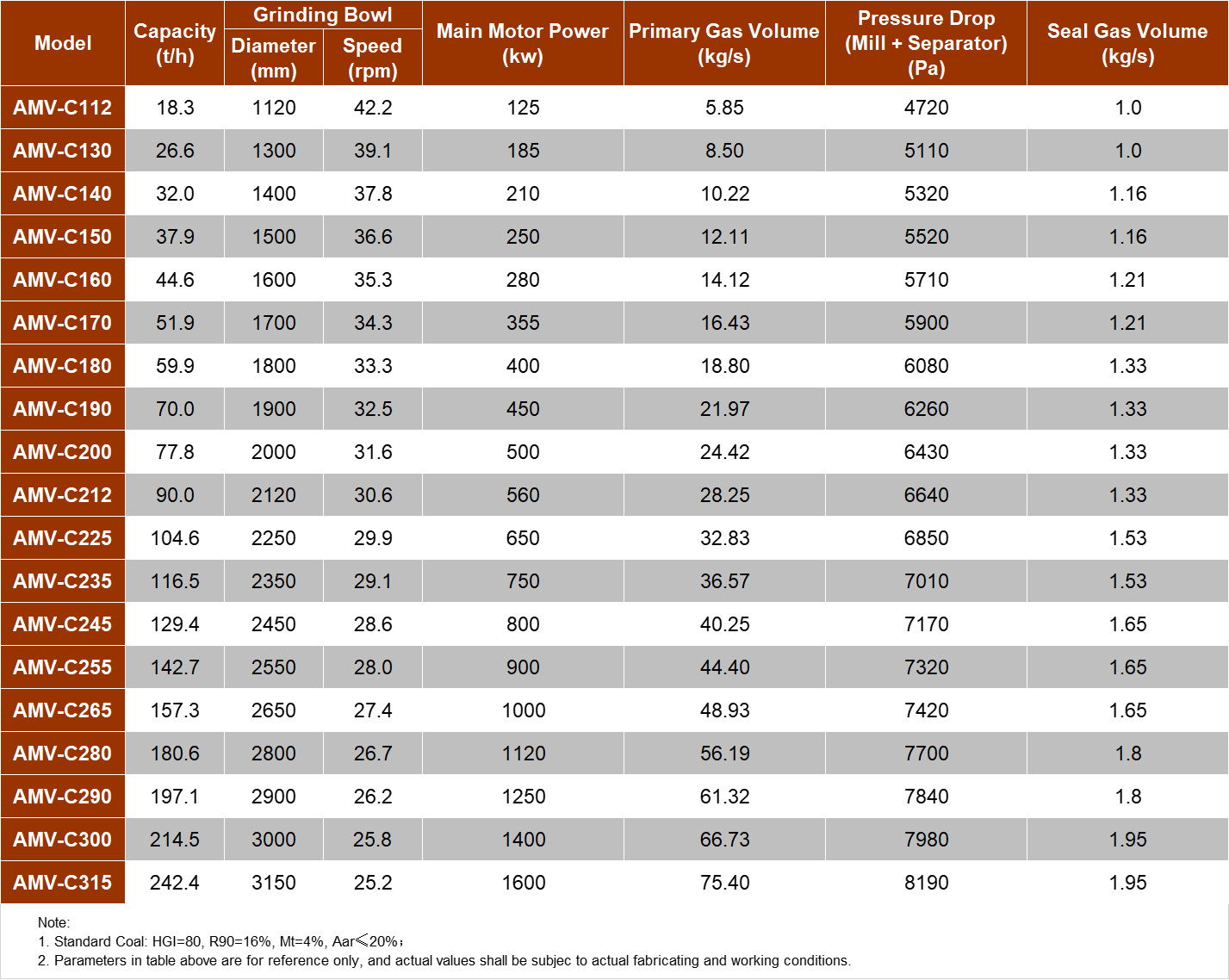

AMV-C Pulverized Coal Vertical Roller Mill

AMV-C Pulverized Coal Vertical Roller Mill is used in micro-powder system of power station, metallurgy, building material and chemical industry, to grind various Bituminous Coal and Anthracite, as well as Dolomite and Bentonite. AMV-C can adopt either positive-pressure straight blowing or negative-pressure system.

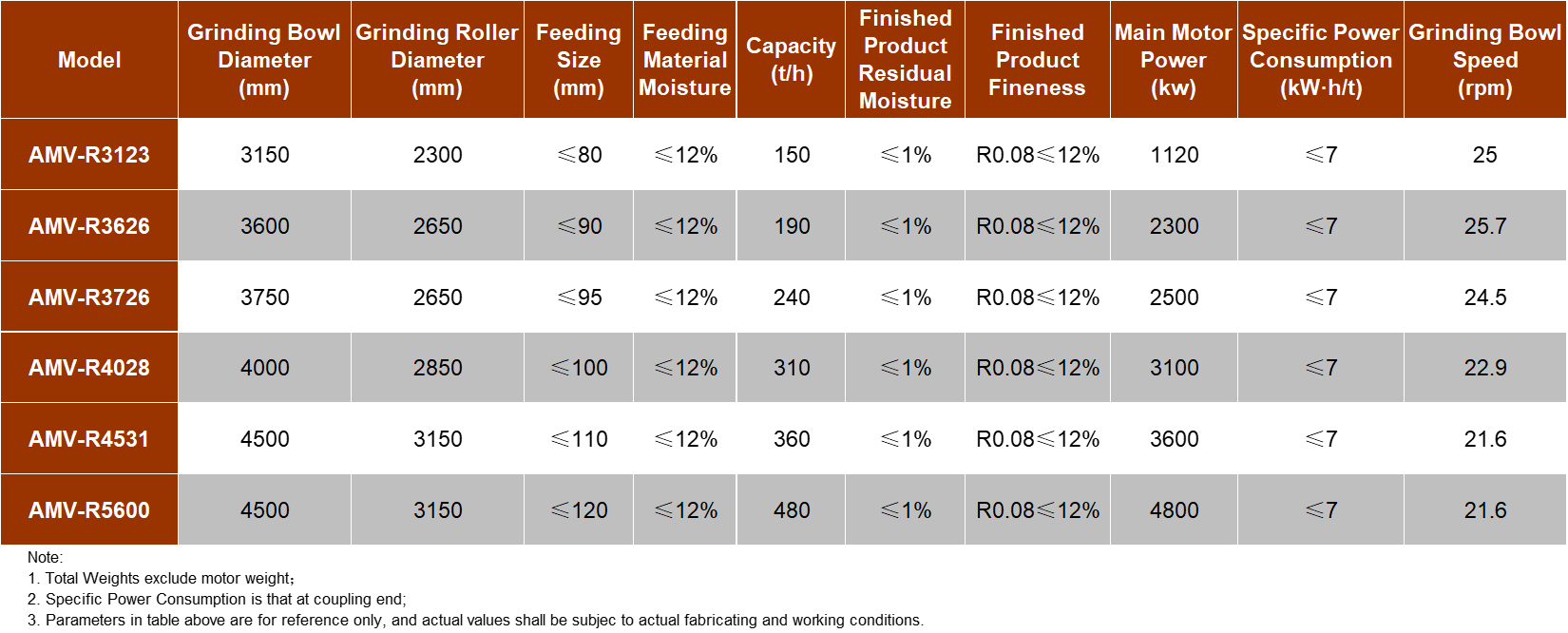

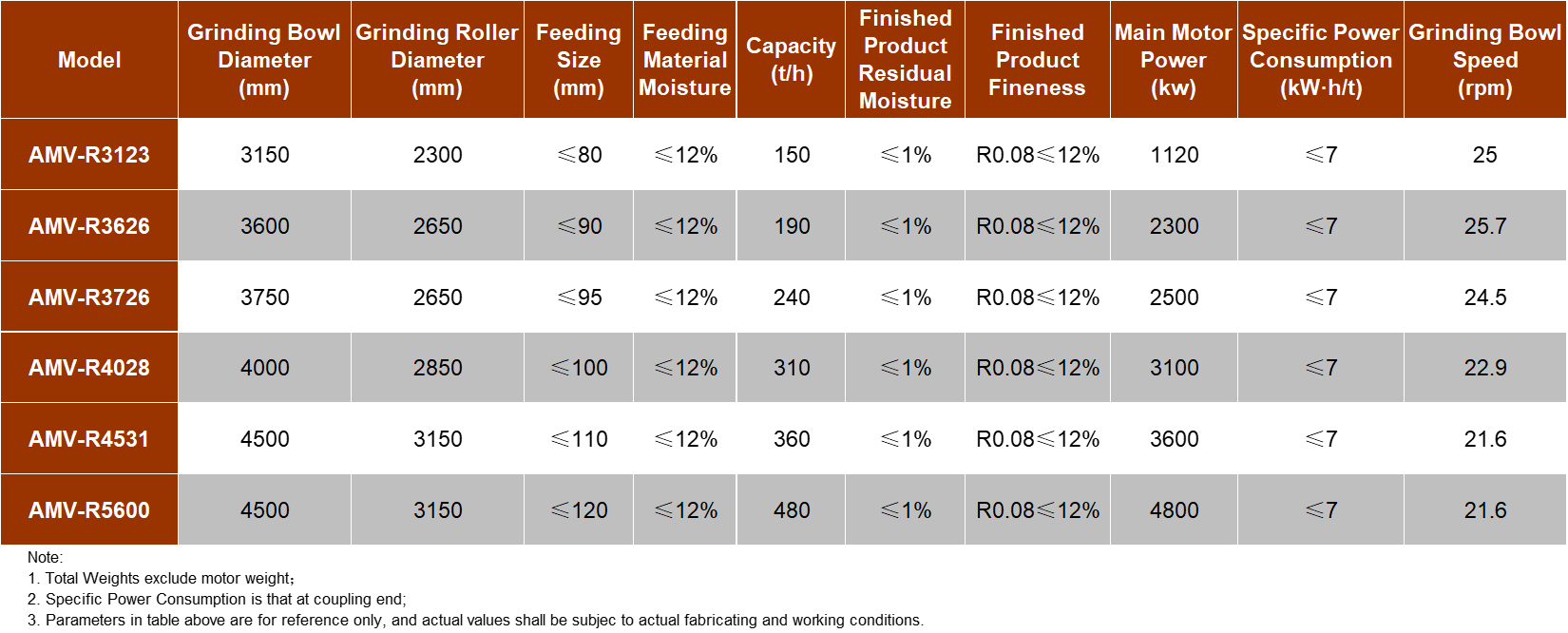

AMV-R Cement Vertical Roller Mill

AMV-R Vertical Roller Mill is mainly used in grinding Cement Raw Meal, and also could be in building material, chemical industry, ceramics, power industry and metallurgy industry, with maximum daily capacity of single set up to 5000 tons.

@copyright Ausino Technological Manufacturing Industry Co., ltd.